Intelligent servo punch P1 (numerical control sheet double-head feeder M3) M15.M16 (upper and lower movable plates) M9 (infrared safety speed regulation function) M12 (pipe rack) M7 (waste discharge and winding)

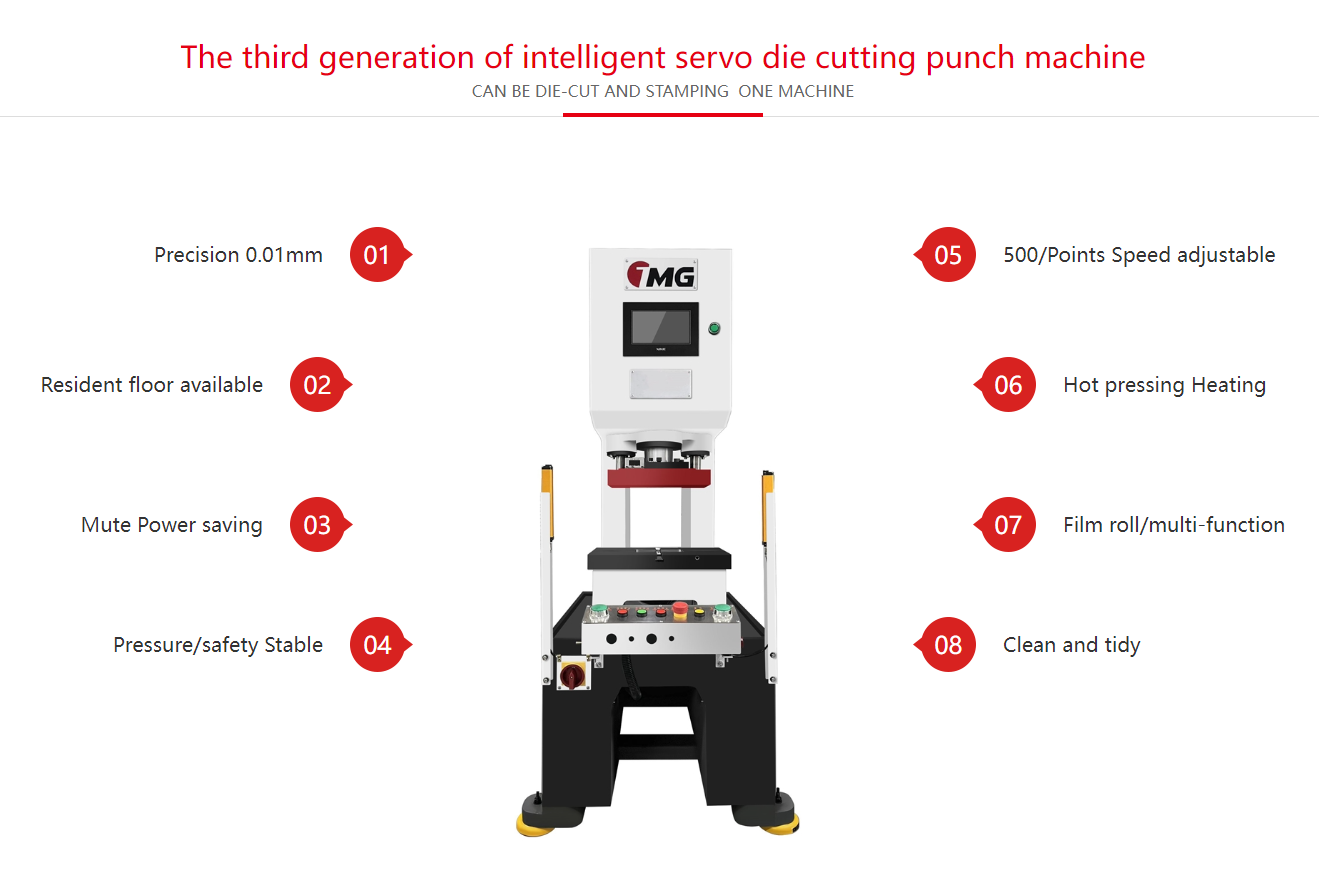

Equipment function: for all kinds of flat sheet or roll material for automatic feeding stamping. Widely used in all kinds of precision electronics, electrical appliances, automotive, medical, printing, packaging, jewelry and other industries. High precision, high speed, high pressure, multi-functional integration. Can be installed all kinds of mold (knife mold, hardware mold, QDC mold, engraving mold, etching mold). This machine can be used for automatic die cutting, waste discharge and winding of roll materials. It can also be used for sheet feeding, die cutting and discharging (photoelectric automatic induction feeding and pressing down to maximize the utilization rate of the whole material). For the domestic first stamping die cutting fully automated equipment.

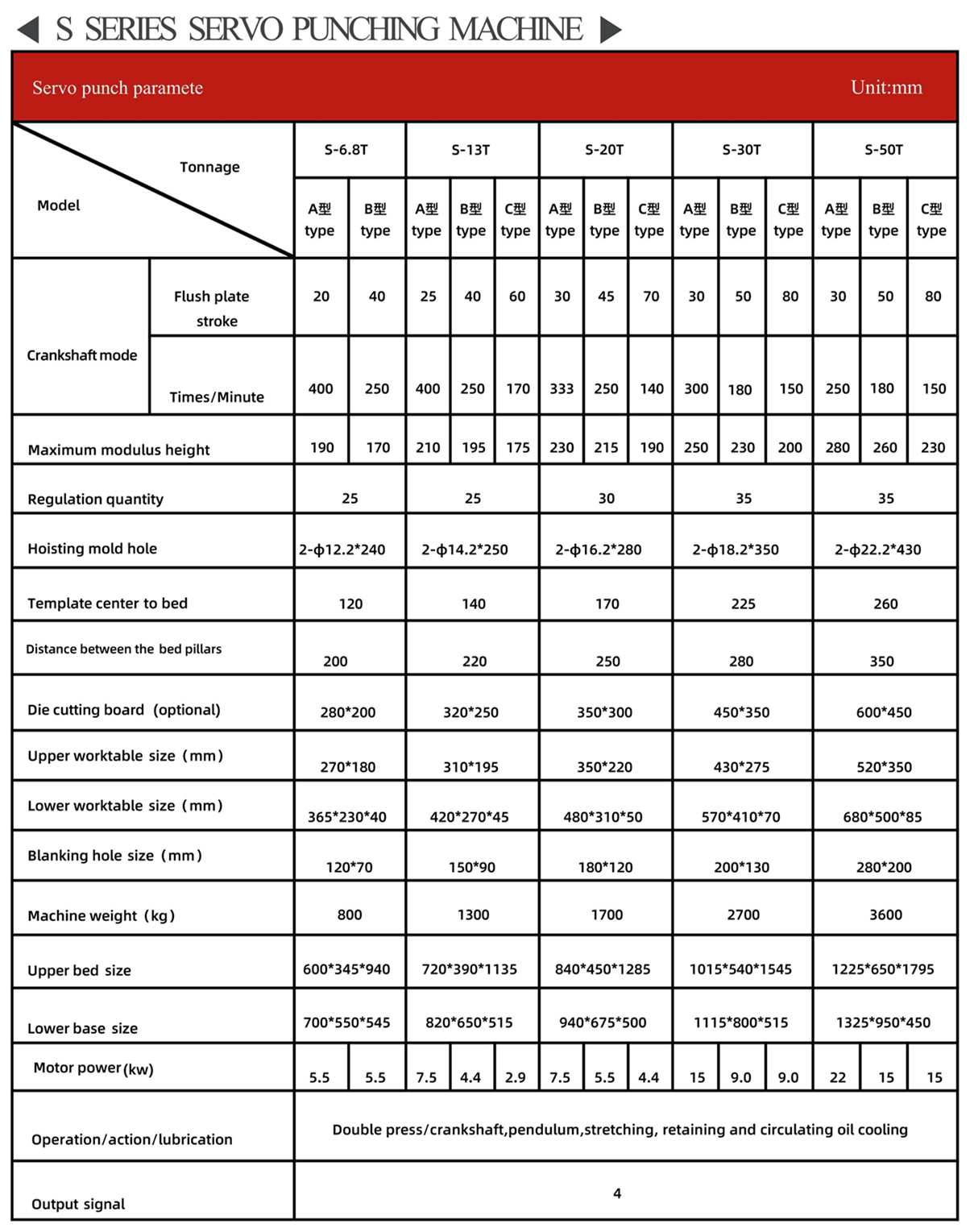

Servo punch characteristics are introduced:

1, the use of integrated high-strength casting machine, stress relief, and the use of imported high-precision bearings to ensure long-term accuracy and high stability;

2. Three-round guide column slider structure, the slider is more stable up and down without deviation, and the vertical accuracy is stable;

3. The dynamic balance system can balance the vibration of the crankshaft and the slider during high-speed operation, effectively reduce the noise of the punch operation (silent operation), effectively control the stability of the bottom dead center, and greatly improve the life of the punch and the mold;

4. Servo overload protection device, overload automatic emergency shutdown, protect the safety of stamping machines and molds, and use it with confidence;

5. The electronic digital display die taller, with one-key die adjustment function, has a die adjustment precision of up to 0.01mm, which is safe, convenient and reliable;

6. The machine running transmission parts adopt centralized control and automatic forced lubrication system design, which can realize real-time control and self-protection function to ensure that the punch is extremely low in wear during high-speed operation.

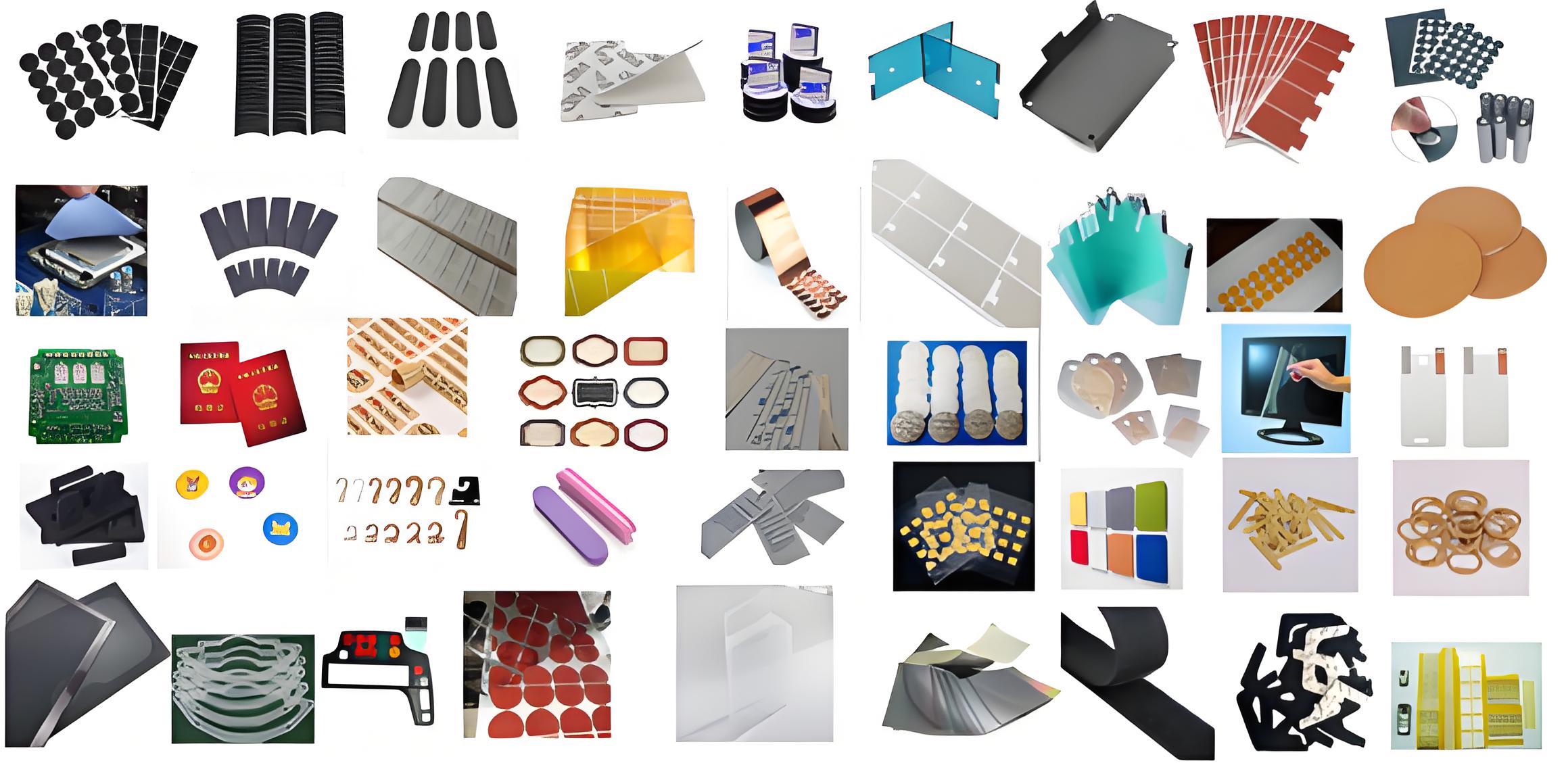

After automation - Machining part of the product(non-metal) application examples

After automation - Machining part of the product ( metal) application examples