Configuration: 1. Feeding machine; 2. S() intelligent servo punch P2 (guide rail type mobile feeder) M9 (infrared safety speed regulation function) pneumatic clutch M15.M16 (upper and lower die cutting and punching plates);3. blanking machine

Equipment function: for all kinds of sheet automatic feeding multiple stamping forming. Special products with printed patterns, single-die multiple stamping. High feeding precision, good operation. Feeding-die cutting-blanking, forming a production line, saving labor.

This machine is the company with many years of die-cutting stamping industry experience carefully developed the 1 sheet screw rail die-cutting stamping punch. Imported screw guide rail is adopted, and the feeding accuracy is controlled at ± 0.02mm; servo drive, man-machine interface operation. It has the characteristics of fast speed, no noise, high precision and simple operation. It is especially suitable for full-automatic continuous die-cutting and stamping of sheet materials and strip materials (such as PET/film, copper foil, EVA, foam, circuit board, etc.). It can be equipped with various molds (such as laser die, hardware die, engraving die, etc.) and has a wide range of applications. The screw stroke is 1200mm (non-standard customized stroke). It is your preferred equipment for die-cutting and stamping production.

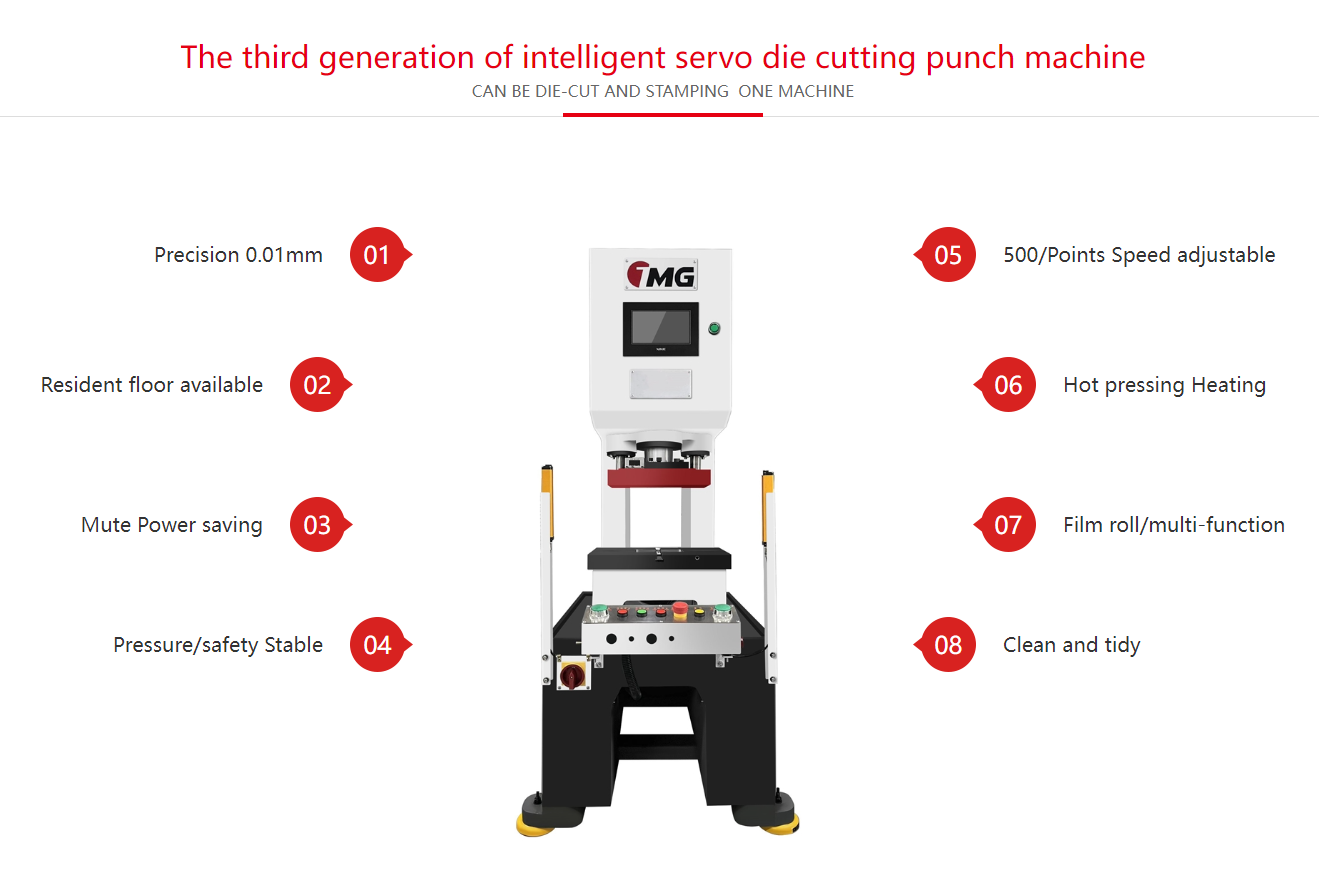

Servo punch characteristics are introduced:

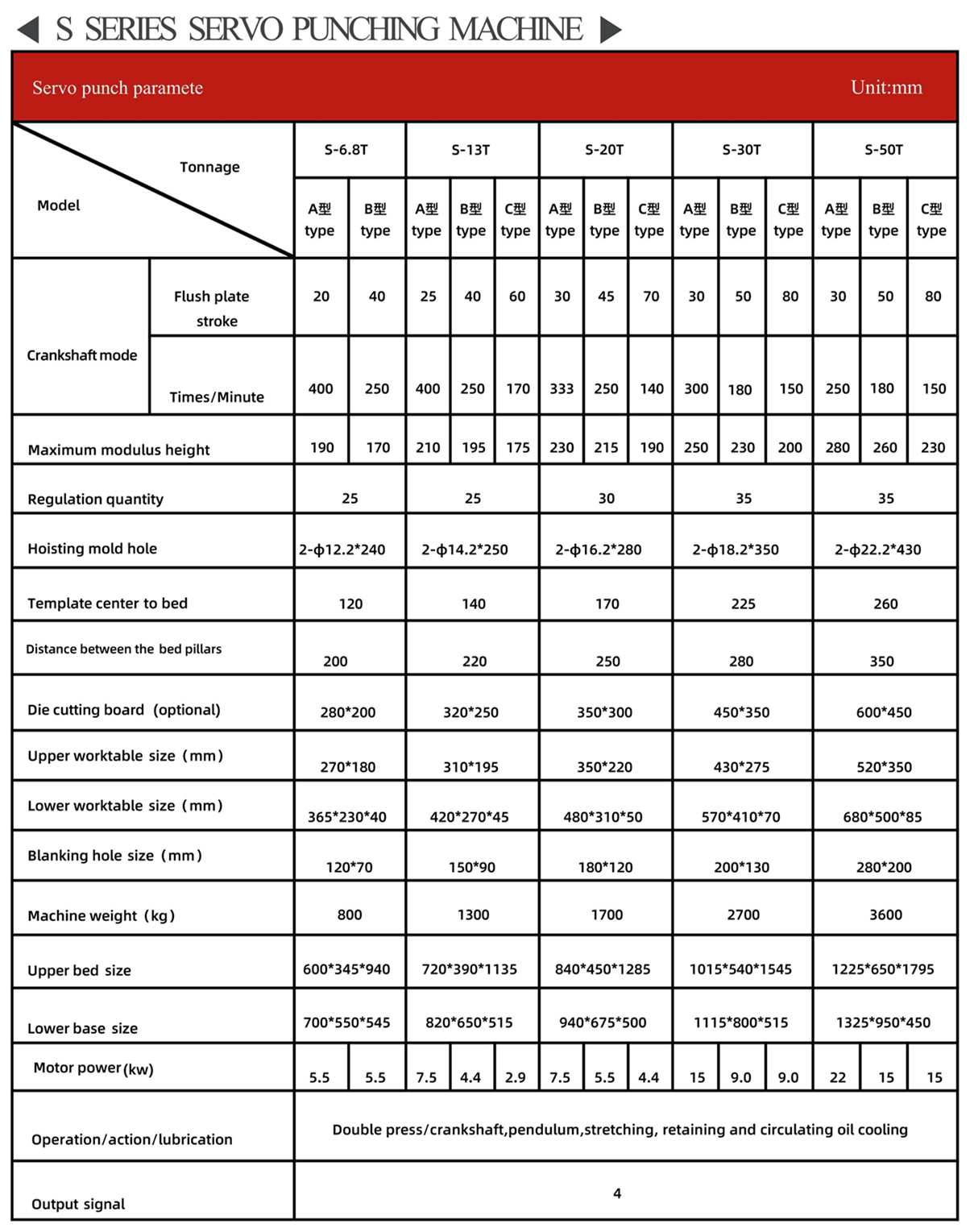

1, the use of integrated high-strength casting machine, stress relief, and the use of imported high-precision bearings to ensure long-term accuracy and high stability;

2. Three-round guide column slider structure, the slider is more stable up and down without deviation, and the vertical accuracy is stable;

3. The dynamic balance system can balance the vibration of the crankshaft and the slider during high-speed operation, effectively reduce the noise of the punch operation (silent operation), effectively control the stability of the bottom dead center, and greatly improve the life of the punch and the mold;

4. Servo overload protection device, overload automatic emergency shutdown, protect the safety of stamping machines and molds, and use it with confidence;

5. The electronic digital display die taller, with one-key die adjustment function, has a die adjustment precision of up to 0.01mm, which is safe, convenient and reliable;

6. The machine running transmission parts adopt centralized control and automatic forced lubrication system design, which can realize real-time control and self-protection function to ensure that the punch is extremely low in wear during high-speed operation.

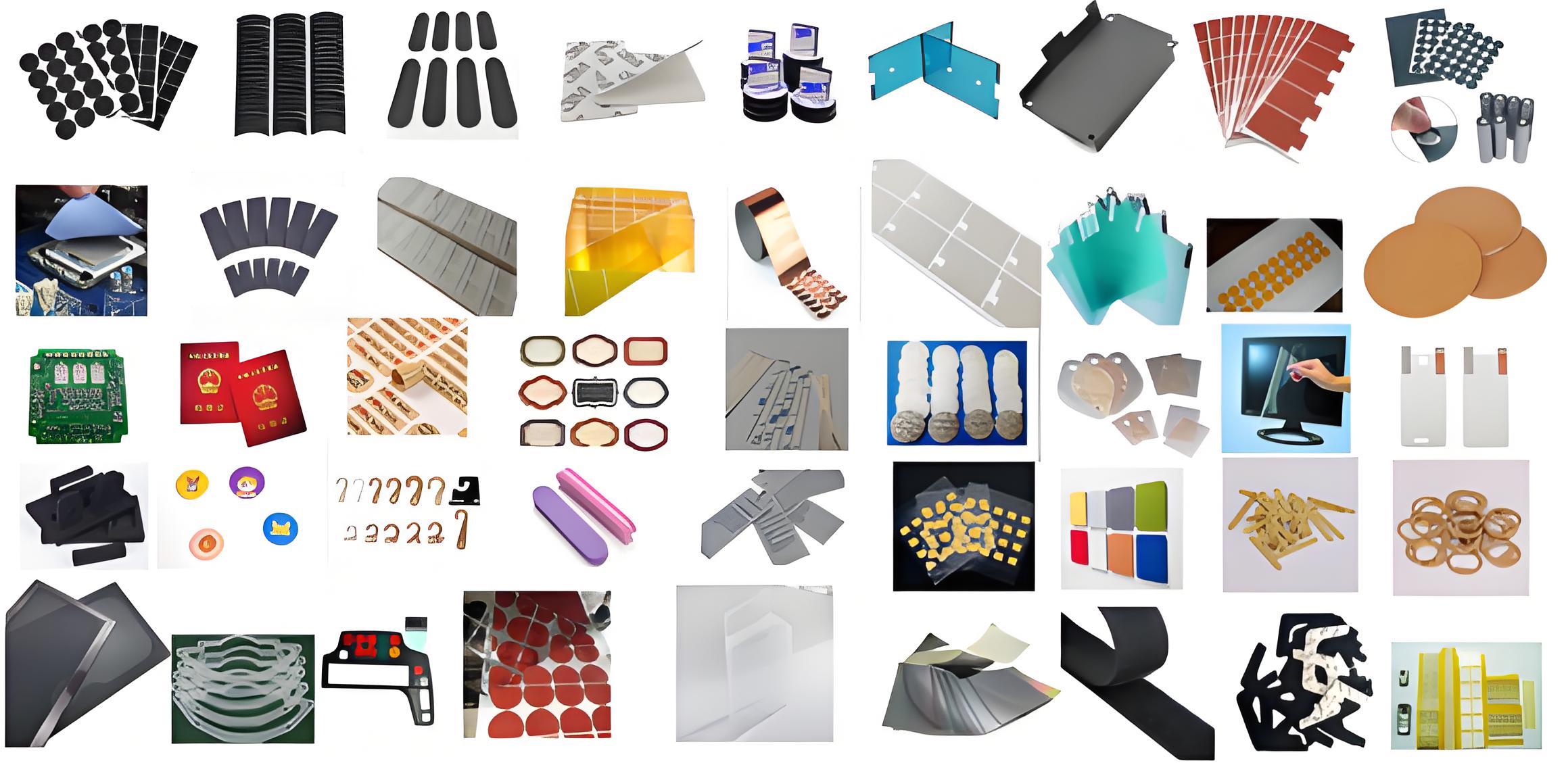

After automation - Machining part of the product(non-metal) application examples

After automation - Machining part of the product ( metal) application examples